Headlines

Traditional Cyanoacrylates vs. RapidFix

Thursday, October 1, 2020

.png)

If you need help determining which type of super glue or adhesive to use for your next DIY, automotive, or house project, we have compiled a list of topics breaking down the differences between name-brand super glues (cyanoacrylates) and our industrial-strength adhesive, RapidFix®. Standard super glue is a strong cyanoacrylate adhesive that works for most projects but may not hold for as long as you need it. RapidFix glue is an industrial-strength adhesive that bonds materials together or acts as a welder when combined with the RapidFix welding powder. Both products are cyanoacrylate adhesives; however, RapidFix also acts like an anaerobic adhesive in that it bonds only with the elimination of oxygen. This unique formulation sets RapidFix apart from traditional cyanoacrylate adhesives and prevents it from drying out in the bottle.

Name brand super glues are cyanoacrylate adhesives that typically bond materials together within 10 seconds to 10 minutes, depending on the situation. Once opened, the countdown begins until the adhesive completely dries out. Most super glues dry outside of the bottle when the solvent (acetone) evaporates, causing the solution to quickly dry when exposed to air.

RapidFix is a cyanoacrylate adhesive with anaerobic attributes. RapidFix instantly bonds materials together by eliminating the oxygen between them or by combining the liquid adhesive with welding powder. It forms non-toxic bonds that can withstand heat upwards of 400°F and is guaranteed to last up to 12 months without drying out in the bottle.

This blog examines the central differences between common cyanoacrylates and RapidFix Adhesive.

Shelf-life

This is certainly one of the biggest problems when it comes to fast-acting adhesives. Glues are typically produced and sold in small amounts because people only need a little bit at a time for most applications. If you use it on a project once, bottle it up, and try to use it again a couple of months later, chances are it has already dried out. This is because most cyanoacrylates use a solvent that slowly evaporates once a bottle has been opened.

Ordinary super glues can begin to dry out in 6-12 months without the bottle ever being opened. After being opened, it dries even quicker. Depending on storage conditions, it may last several weeks after being opened, if you are lucky. Therefore, some brands sell their super glue in bottles that seem to be continuously shrinking in size.

RapidFix does not rely on the solvent to dry, rather it bonds with the elimination of oxygen. This is part of the reason why it lasts so long in the bottle even after being opened. After initial use, RapidFix could potentially last several years in the right conditions hence why we back our product with a 12-month guarantee that it will not dry out in the bottle.

Viscosity

The viscosity of a liquid refers to its thickness and resistance to movement. For some projects such as patching a hole or gap, a thinner runnier glue might be more effective whereas if you are working on something vertically or up-side-down, a thicker glue could work better to prevent drippage.

Super glues can come in a variety of viscosities. Although they come out of the bottle differently, they still dry the same. Even with a runnier liquid, you should only need a very small amount to stick to surfaces. It can start to get expensive fast when you start buying different types of glue because there are so many available on the market now.

RapidFix The versatility of RapidFix ensures you will only have to purchase one adhesive for the majority of your household fixes. If you are adhering a piece to the underside of an object, you can apply RapidFix to the base portion then push it up to the top, eliminating the oxygen and forming an instant bond. If you are working vertically to “weld” something together, RapidFix can still be applied to the object and topped off with the welding powder. The extra adhesive can then be wiped away. It is also commonly used to fill holes that can later be drilled, sanded, and painted.

Bond Strength

Possibly the most crucial aspect when choosing a super glue or adhesive is the strength of the bond. Ideally, you would want the patched area to be even stronger than it was before the repair. You may need to repair a heavy-duty object such as a radiator, thus avoiding purchasing a new one and saving your hard-earned money.

People choose name brand super glue over tape or school glue because they want a stronger hold. Traditional adhesives can get the job done on some occasions, but the hold does not always last when stress is applied.

RapidFix has been battle-tested on numerous heavy-duty projects. It withstands impacts, vibrations, shock, and extreme temperature conditions. A quick YouTube or Amazon Review search reveals testimonials by people who have used it to repair radiators, distributors, appliances, and nearly anything broken. Professional strength and heat resistance upwards of 400°F make RapidFix a great option for any sort of repair, big or small.

Dry Time

Perhaps the most important attribute takes into consideration our busy schedules and the bonding time of super glues. An adhesive’s cure time depends on several factors including the material being used, the temperature of the environment, and the exact type of glue used. Sometimes an activator (or powder) is used to rapidly speed up the curing process.

Super glues generally dry in a very short amount of time. Gorilla glue boasts a time of 10-45 seconds and is most likely quicker when two flat pieces are pushed together. However, these bonds do not typically reach their full strength for roughly 24 hours and require careful handling until fully cured.

RapidFix will adhere nearly any smooth surface to another smooth surface. The bond is instant as the oxygen is pushed out of the focused area. While the bond might not reach full strength for 18-24 hours, it can usually withstand a strong force applied to it directly after application. If you are not bonding two solid surfaces, use the welding powder to create a chemical reaction that creates a strong bond instantly. We also offer a UV Light-activated adhesive that only bonds when UV light is applied. This attribute enables the user to manipulate the repair up until the point of UV light application.

Materials

There is not one glue that can solve every problem. Projects involving super glues can range from plastics and rubber to metals and ceramics. Each glue will have its own shortcomings but there are some that will get most jobs done. Standard super glues are applied to just about everything. DIY projects seem to be the most common use with cyanoacrylates. The main materials that standard super glues struggle with include wood, papers, foam, and anything that heats up. Unless you buy a special waterproof super glue, most standard glues are simply water-resistant, meaning that they can be splashed or submerged for a short amount of time, but eventually the bond will break.

When it comes to bonding wood and other porous surfaces, RapidFix is not a viable solution. However, it bonds to almost everything else. A full list of acceptable materials can be found here. RapidFix is the best super glue option for fixes that require a waterproof or heat resistant solution. It is commonly used to permanently repair water hoses, copper piping, and automotive parts.

Non-Toxic

Using a non-toxic glue is of the utmost importance when it comes to using it on water piping, kitchen materials, and even on skin cuts and wounds. Many types of glue and adhesives contain solvents that can be toxic to humans either through the skin or inhalation. Certain epoxy products can cause different levels of irritation due to its resin.

Each super glue is different when it comes to toxins. Most companies nowadays have come to realize the importance of having a non-toxic product because of the wide range of uses people have for them. It is important to do the research before using a name brand super glue because some of them can be toxic when used in certain situations.

The non-toxic formula for RapidFix means it is generally safe to use. It has been used to repair kitchen plates, utensils, and appliances. Some people have told us they have used it for small finger cuts when they did not have any bandages currently at their disposal. This super glue is even aquarium safe and can be used to bond glass as well.

Versatility

Being able to use super glue in different scenarios is why most people turn to it in their hour of need. As mentioned earlier, there is a wide range of materials that can be fixed but there are also other handy fixes some can be applied to.

Being able to use super glue in different scenarios is why most people turn to it in their hour of need. As mentioned earlier, there is a wide range of materials that can be fixed but there are also other handy fixes some can be applied to.

Most super glues are limited to gluing materials together. While obviously that still leaves you with a wide range of options, it does not quite offer much versatility in the professional world. Although the combination of super glue and baking soda can help increase the strength of a bond, it cannot be used in the same way as dual adhesives.

The combination of glass silica welding powder with RapidFix adhesive gives it a whole new set of uses. Drill a hole in the wrong spot and need to patch it? Drop some welding powder in then layer in the liquid adhesive to build the hole back up. Once cured, the solution is strong enough to be drilled, sanded and finally painted over. RapidFix dries clear.

Price

Price is the driving factor of many purchases and an important consideration. Many super glues are relatively cheap but will only provide you one or two uses before it dries out.

Straight to the point, name brand super glues have us beat on pricing for individual purchases and it is one of the very few things that give them a competitive advantage. You can find most available for somewhere between $4 and $10 depending on brand and the type of super glue.

RapidFix dual adhesive system comes in 5mL (~$13), 10mL (~$20) and 25mL (~$23). When you pay for RapidFix, you pay for an industrial-strength super glue that is backed with a 12-month guarantee and offers the widest range of applications on the market. More often than not, super glues end up drying out on a storage shelf before they get used a second time which is why we offer 5mL to 25mL so that you can buy only the amount that you will need.

Name brand super glues are cyanoacrylate adhesives that typically bond materials together within 10 seconds to 10 minutes, depending on the situation. Once opened, the countdown begins until the adhesive completely dries out. Most super glues dry outside of the bottle when the solvent (acetone) evaporates, causing the solution to quickly dry when exposed to air.

RapidFix is a cyanoacrylate adhesive with anaerobic attributes. RapidFix instantly bonds materials together by eliminating the oxygen between them or by combining the liquid adhesive with welding powder. It forms non-toxic bonds that can withstand heat upwards of 400°F and is guaranteed to last up to 12 months without drying out in the bottle.

This blog examines the central differences between common cyanoacrylates and RapidFix Adhesive.

Shelf-life

.jpg)

This is certainly one of the biggest problems when it comes to fast-acting adhesives. Glues are typically produced and sold in small amounts because people only need a little bit at a time for most applications. If you use it on a project once, bottle it up, and try to use it again a couple of months later, chances are it has already dried out. This is because most cyanoacrylates use a solvent that slowly evaporates once a bottle has been opened.

Ordinary super glues can begin to dry out in 6-12 months without the bottle ever being opened. After being opened, it dries even quicker. Depending on storage conditions, it may last several weeks after being opened, if you are lucky. Therefore, some brands sell their super glue in bottles that seem to be continuously shrinking in size.

RapidFix does not rely on the solvent to dry, rather it bonds with the elimination of oxygen. This is part of the reason why it lasts so long in the bottle even after being opened. After initial use, RapidFix could potentially last several years in the right conditions hence why we back our product with a 12-month guarantee that it will not dry out in the bottle.

Viscosity

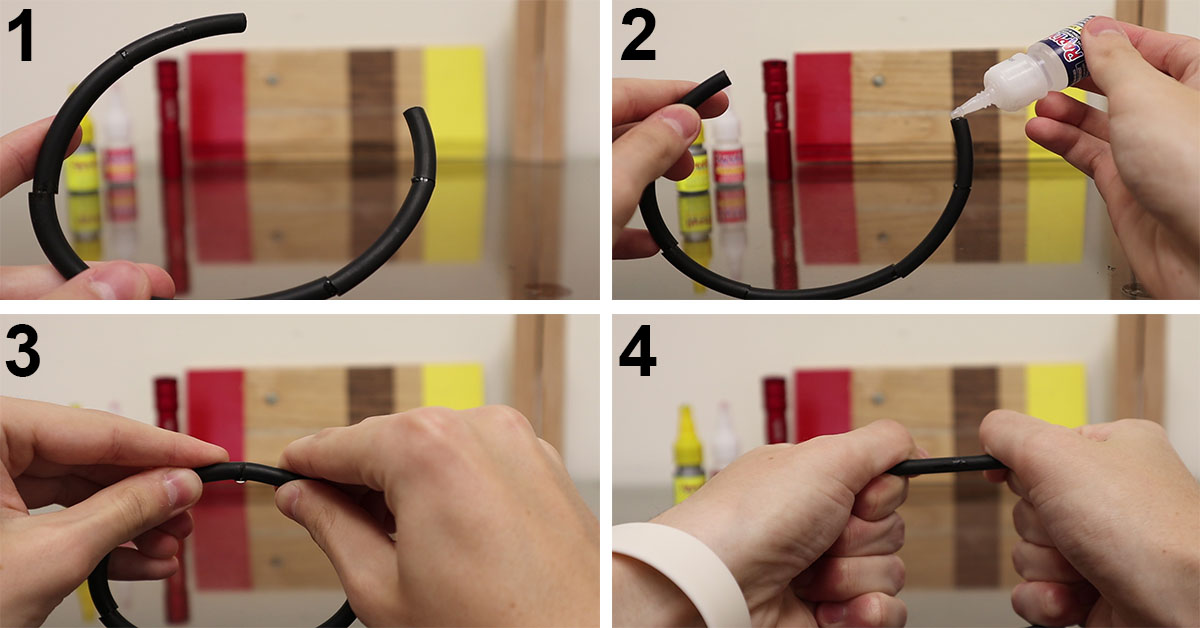

.jpg)

The viscosity of a liquid refers to its thickness and resistance to movement. For some projects such as patching a hole or gap, a thinner runnier glue might be more effective whereas if you are working on something vertically or up-side-down, a thicker glue could work better to prevent drippage.

Super glues can come in a variety of viscosities. Although they come out of the bottle differently, they still dry the same. Even with a runnier liquid, you should only need a very small amount to stick to surfaces. It can start to get expensive fast when you start buying different types of glue because there are so many available on the market now.

RapidFix The versatility of RapidFix ensures you will only have to purchase one adhesive for the majority of your household fixes. If you are adhering a piece to the underside of an object, you can apply RapidFix to the base portion then push it up to the top, eliminating the oxygen and forming an instant bond. If you are working vertically to “weld” something together, RapidFix can still be applied to the object and topped off with the welding powder. The extra adhesive can then be wiped away. It is also commonly used to fill holes that can later be drilled, sanded, and painted.

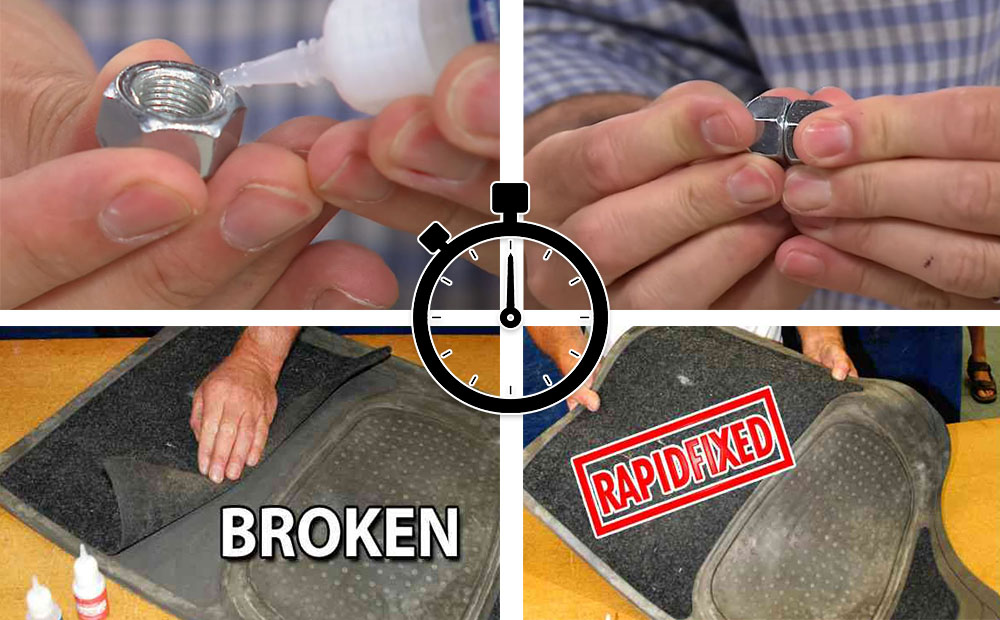

Bond Strength

Possibly the most crucial aspect when choosing a super glue or adhesive is the strength of the bond. Ideally, you would want the patched area to be even stronger than it was before the repair. You may need to repair a heavy-duty object such as a radiator, thus avoiding purchasing a new one and saving your hard-earned money.

People choose name brand super glue over tape or school glue because they want a stronger hold. Traditional adhesives can get the job done on some occasions, but the hold does not always last when stress is applied.

RapidFix has been battle-tested on numerous heavy-duty projects. It withstands impacts, vibrations, shock, and extreme temperature conditions. A quick YouTube or Amazon Review search reveals testimonials by people who have used it to repair radiators, distributors, appliances, and nearly anything broken. Professional strength and heat resistance upwards of 400°F make RapidFix a great option for any sort of repair, big or small.

Dry Time

Perhaps the most important attribute takes into consideration our busy schedules and the bonding time of super glues. An adhesive’s cure time depends on several factors including the material being used, the temperature of the environment, and the exact type of glue used. Sometimes an activator (or powder) is used to rapidly speed up the curing process.

Super glues generally dry in a very short amount of time. Gorilla glue boasts a time of 10-45 seconds and is most likely quicker when two flat pieces are pushed together. However, these bonds do not typically reach their full strength for roughly 24 hours and require careful handling until fully cured.

RapidFix will adhere nearly any smooth surface to another smooth surface. The bond is instant as the oxygen is pushed out of the focused area. While the bond might not reach full strength for 18-24 hours, it can usually withstand a strong force applied to it directly after application. If you are not bonding two solid surfaces, use the welding powder to create a chemical reaction that creates a strong bond instantly. We also offer a UV Light-activated adhesive that only bonds when UV light is applied. This attribute enables the user to manipulate the repair up until the point of UV light application.

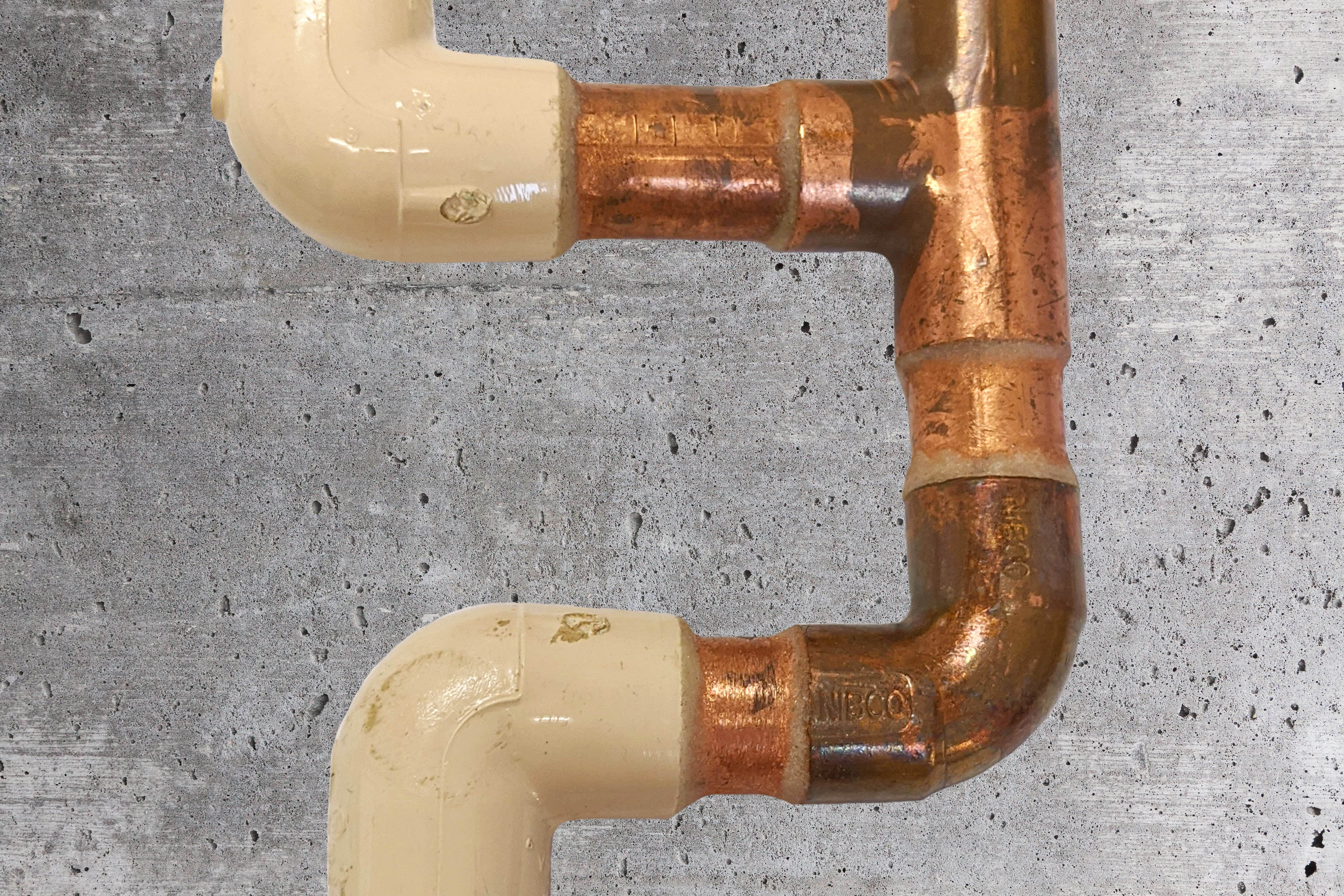

Materials

There is not one glue that can solve every problem. Projects involving super glues can range from plastics and rubber to metals and ceramics. Each glue will have its own shortcomings but there are some that will get most jobs done. Standard super glues are applied to just about everything. DIY projects seem to be the most common use with cyanoacrylates. The main materials that standard super glues struggle with include wood, papers, foam, and anything that heats up. Unless you buy a special waterproof super glue, most standard glues are simply water-resistant, meaning that they can be splashed or submerged for a short amount of time, but eventually the bond will break.

When it comes to bonding wood and other porous surfaces, RapidFix is not a viable solution. However, it bonds to almost everything else. A full list of acceptable materials can be found here. RapidFix is the best super glue option for fixes that require a waterproof or heat resistant solution. It is commonly used to permanently repair water hoses, copper piping, and automotive parts.

Non-Toxic

Using a non-toxic glue is of the utmost importance when it comes to using it on water piping, kitchen materials, and even on skin cuts and wounds. Many types of glue and adhesives contain solvents that can be toxic to humans either through the skin or inhalation. Certain epoxy products can cause different levels of irritation due to its resin.

Each super glue is different when it comes to toxins. Most companies nowadays have come to realize the importance of having a non-toxic product because of the wide range of uses people have for them. It is important to do the research before using a name brand super glue because some of them can be toxic when used in certain situations.

The non-toxic formula for RapidFix means it is generally safe to use. It has been used to repair kitchen plates, utensils, and appliances. Some people have told us they have used it for small finger cuts when they did not have any bandages currently at their disposal. This super glue is even aquarium safe and can be used to bond glass as well.

Versatility

.jpg) Being able to use super glue in different scenarios is why most people turn to it in their hour of need. As mentioned earlier, there is a wide range of materials that can be fixed but there are also other handy fixes some can be applied to.

Being able to use super glue in different scenarios is why most people turn to it in their hour of need. As mentioned earlier, there is a wide range of materials that can be fixed but there are also other handy fixes some can be applied to.Most super glues are limited to gluing materials together. While obviously that still leaves you with a wide range of options, it does not quite offer much versatility in the professional world. Although the combination of super glue and baking soda can help increase the strength of a bond, it cannot be used in the same way as dual adhesives.

The combination of glass silica welding powder with RapidFix adhesive gives it a whole new set of uses. Drill a hole in the wrong spot and need to patch it? Drop some welding powder in then layer in the liquid adhesive to build the hole back up. Once cured, the solution is strong enough to be drilled, sanded and finally painted over. RapidFix dries clear.

Price

Price is the driving factor of many purchases and an important consideration. Many super glues are relatively cheap but will only provide you one or two uses before it dries out.

Straight to the point, name brand super glues have us beat on pricing for individual purchases and it is one of the very few things that give them a competitive advantage. You can find most available for somewhere between $4 and $10 depending on brand and the type of super glue.

RapidFix dual adhesive system comes in 5mL (~$13), 10mL (~$20) and 25mL (~$23). When you pay for RapidFix, you pay for an industrial-strength super glue that is backed with a 12-month guarantee and offers the widest range of applications on the market. More often than not, super glues end up drying out on a storage shelf before they get used a second time which is why we offer 5mL to 25mL so that you can buy only the amount that you will need.